Using the state-of-the-art technology and laboratory quality testing unique to them, Tilma Lanka produces the best quality coconut oil in Sri Lanka.

For the production, Sun dried Copra is collected from the selected suppliers located in various parts of Sri Lanka after inspecting each batch for quality.

Milling Copra comes in half ball shape and other irregular shapes. This is not ideal for handling and processing. So it is cut into small pieces of about 1 inch size. A Copra Cutter driven by a motor does this. The beaters cut the copra into pieces, when the pieces become smaller than the desired size; they escape out through the mesh. These copra pieces are carried out through a Screw Conveyor.

Copra is loaded into a hopper and the hopper has a mesh at bottom to allow air to come inside but prevent copra from falling down. Hot air is generated using steam radiator and pumped into hopper using a centrifugal blower. Moisture level reduces .Moisture when present in oil causes rancidity, so when moisture is removed shelf life of oil increases.

Dried Copra pieces are now fed into an expeller with screw press for mechanical crushing under high pressure. Oil squeezes out of copra during this process leaving the fiber out. The left out Oil cake will still have 8% oil. Extracting oil beyond this level is not economical with this mechanical crushing. Solvent extraction method will have to be employed beyond this stage but we do not operate that stage,

Copra contains approximately 63% oil, 5% is lost as moisture during the process, and remaining 32% is oil cake.

Oil cake is packed in bags to export market to use by solvent extractors or cattle feed manufacturers.

Oil extracted through expeller will has about 8% sediments/foots. They are separated from oil through a filtering process

Critical control points are identified all across the process. Important parameters and their valid range is defined, process is tuned to make the parameter values fall within the range. A laboratory with necessary equipment is used for testing and measurement. Arrangements, Upkeep, hygiene and cleanliness of materials and machines are ensured. Quality control is expensive and time consuming but gives the much needed consistency and satisfaction to consumer.

Final filtered oil is either sold in bulk through tankers to industrial buyers or in small consumer packs to end consumers through distribution network. Coconut Oil is packed in Pouches, PET Bottles, HDPE Bottles, Wide Mouth Jars, Jerry Cans and Tins.

Primary packing is secondary packed in corrugated carton boxes.

Packed boxes are stacked on a pallet. To prevent bulging of carton boxes stacking is done in such a way that load is equally distributed on top surface of carton box. A hand pallet truck is employed to move and dispatch to delivery door.

Click here to view more details about our sales and distribution process.

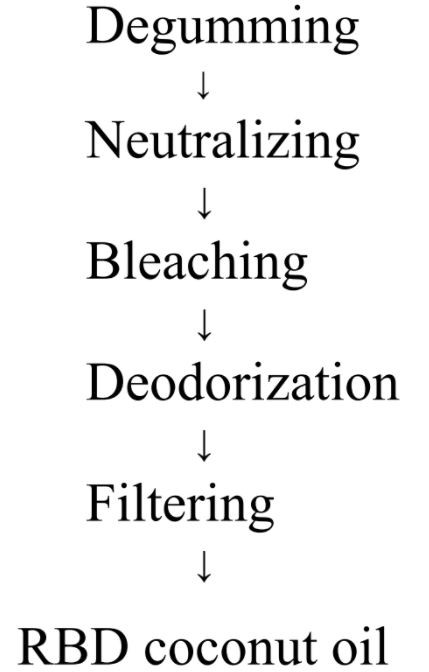

This process involves filtering and bleaching the oil, which is then heated to a high temperature. The high heat temperature deodorizes the oil and kills germs and any other bacteria. The end product is a coconut oil highly processed and refined in comparison to the more natural virgin coconut oils.

Tilma Lanka is a company which carries out multiple business activities that includes Manufacturing & Distributing coconut oil & importing vegetable oil. Mathugama Oil Mills is founded in 2008 and has its registered office at Masala watta, Horawala, Welipenna.